Anyone who has run a restaurant, grocery store, café, an ice cream shop, or any other food service operation knows that keeping your equipment and operating area clean is important. It's important for three major reasons:

- Food safety – keep it safe

- Good marketing – keep it attractive

- Equipment life – keep it longer

Juicing is a team effort, unless you’re running a one-person show. Even then you rely on good suppliers and partners. Communicate to your team the importance of cleaning your juicing area and equipment on a regular basis. It’s good for your business on so many levels.

If you’re juicing commercially, then you or your staff have probably considered what’s the best way to clean your commercial citrus juicer. This article focuses on 10 guiding principles for keeping your commercial juicer clean.

10 GUIDING PRINCIPLES OF CLEANING YOUR COMMERCIAL JUICER

- A clean juicer sells juice, a dirty one doesn’t

- Communicate the importance to the team of Taste, Hygiene, and Efficiency (“THE Strategy”)

- Buy the right equipment to support proper hygiene and efficiency targets

- Read the User Manual and/or watch available training videos

- Use the right cleaning materials and supplies to clean your juicer

- Implement the right processes, based on the User Manual, adapted to your operations

- Train your team on following these processes

- Check for process compliance and monitor progress

- Periodically review the processes for efficiency and appropriateness

- Retrain on a periodic basis and be sure to train new employee

These guiding principles reflect the best practices we’ve observed across many customer segments. These principles should help you develop the right cleaning strategies, regardless of being a single location or major chain, a food service or grocery retail operation, juicing back-of-house or customer-facing.

#1 A CLEAN JUICER SELLS JUICE, A DIRTY ONE DOESN'T

Customers want to buy juice from clean-looking equipment that is in a clean-looking store, bar, or other commercial operation. Dirty locations and dirty-looking equipment can be a turn-off, so keep it clean. Let your clean equipment act like a billboard for freshness.

A little effort can bring you a long way. A clean juicer helps you sell more juice and supports your brand image. A dirty one does the opposite.

#2 TASTE, HYGIENE, EFFICIENCY

Citrus America’s strategy for the past decade has been to help our customers focus on THE Strategy. THE Strategy is based on Taste, Hygiene, and Efficiency. Taste, Hygiene, and Efficiency are the three basic principles of running a successful juicing program.

Communicate the importance of a juicing program for your business with your team. Highlight the importance of Taste, Hygiene, and Efficiency for the success of the juicing program.

Taste: If it tastes amazing, your customers will come back for more

Hygiene: It has to be safe, so you can juice with confidence

Efficiency: It has to be efficient, so you can juice profitably

THE Strategy: This is the key to successful juicing programs

This article’s focus is Hygiene and Efficiency. Taste is an extremely important topic but will be addressed in more detail in other articles.

A little effort can bring you a long way. A clean juicer helps you sell more juice and supports your brand image. A dirty one does the opposite.

This article focuses on how to keep your juicing equipment clean and safe so you can juice with confidence. The article is also about cleaning efficiently and effectively to help ensure program success and profitability.

#3 BUY THE RIGHT EQUIPMENT

When you’re looking at which equipment to buy, remember, you’ll be cleaning the juicer every day. Select quality equipment that meets the proper hygiene standards. Select equipment that can be taken apart easily for effective cleaning. Choose equipment that can withstand high temperature cleaning and can be properly sanitized.

Most grocery retailers and food service operators look for equipment that meets a specific set of hygiene standards. NSF has set certain minimum food equipment standards. In addition, some equipment suppliers go above and beyond these standards. They use higher quality materials, engineer design improvements, and include special features to further improve hygiene, efficiency, durability, and reliability.

Look for increased use of 304 food grade stainless steel instead of plastic components. Alternatively, the use of higher density co-polymers where plastics are required is important. Look for equipment that has reduced areas that can easily trap food or liquids and make it more difficult to clean. Look for design features that allow for faster, more efficient cleaning and proper sanitization.

We have heard from many customers that their old juicing equipment can take more than one hour to clean… and it’s still not clean. A modern, well-designed juicer should take between 5-30 minutes, depending on size and features, to get fully clean and sanitized.

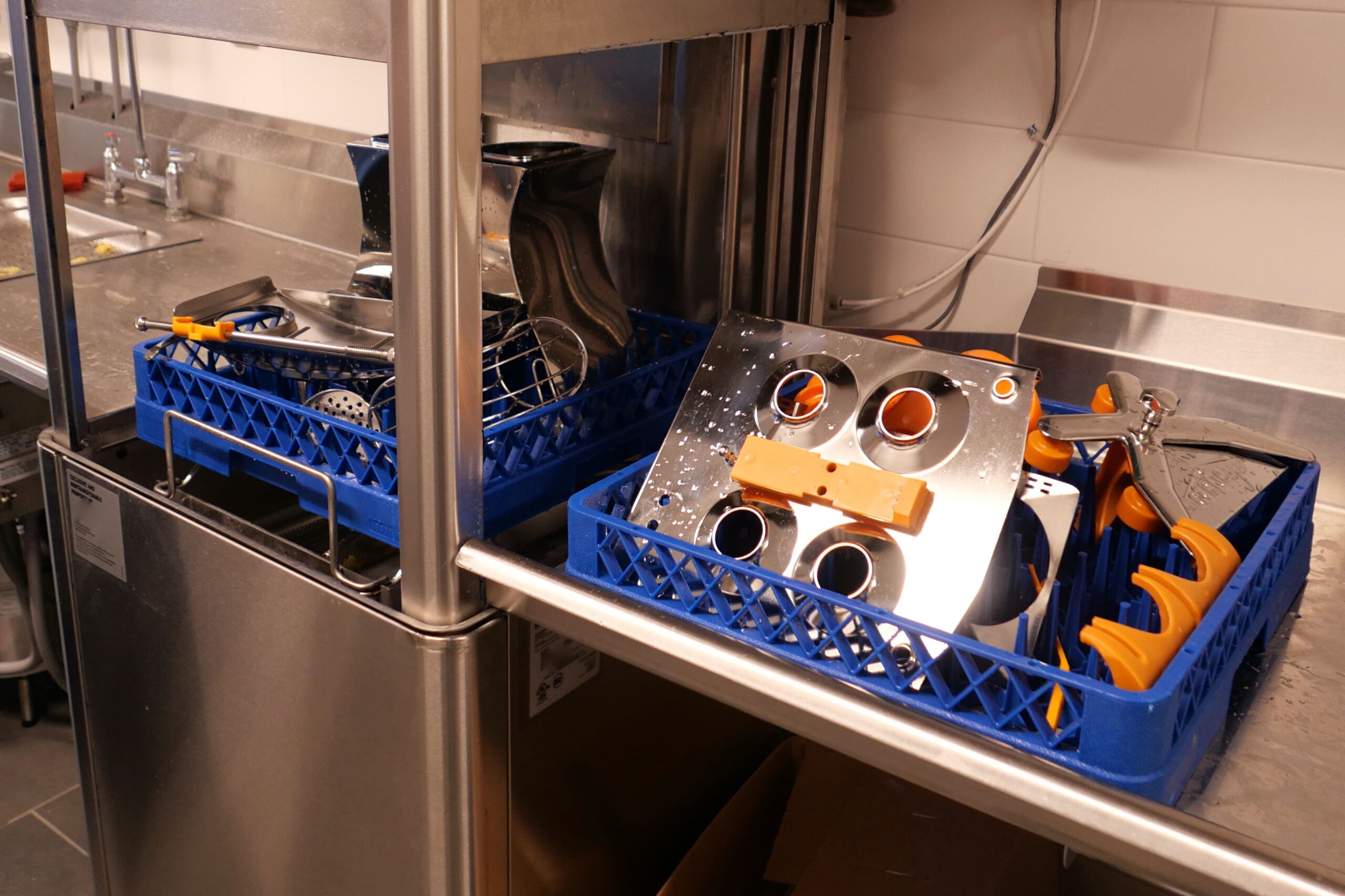

If you use commercial dishwashing equipment then be sure to know what components can be easily removed and are dishwasher safe. This is very important to understand. Review how to assemble the equipment, so you can better judge hygiene and efficiency.

Click here to see how to take apart a Fantastic M/AS juicer

#4 READ THE USER MANUAL/WATCH TRAINING VIDEOS

The designers and manufacturers of high-quality juicing equipment have put a lot of effort into documenting how to properly operate their equipment. This includes taking the equipment apart and putting it back together for cleaning. Quality companies have also invested significant effort into creating detailed quality training videos. This helps ensure customers can quickly get trained on operating their juicers.

We’ve observed customers who wrote their own cleaning procedures but completely ignored the User Manual. This will almost certainly lead to inefficient processes and may even lead to damaged equipment. This is easy to avoid.

We at Citrus America are here to help our customers implement the right processes quickly and efficiently. It starts with the training manuals and videos we make available. In addition, we have tech support ready to help our customers answer any questions they may have related to juicing on our equipment.

Kick off a healthy process by familiarizing yourself with the factory-supplied materials.

#5 USE THE RIGHT MATERIALS/SUPPLIES

In general, we’ve found the best materials to use to clean your juicer on a regular basis are hot water and a soft towel. We recommend using a non-abrasive dish liquid and clear clean water to rinse. Many customers use a traditional three-compartment sink. The "wash-rinse-sanitize" steps work very well and are a great way to clean and sanitize your equipment. If using a commercial dishwasher, know which juicer components are dishwasher safe. Understand what parts can withstand the high sanitizing temperatures of a commercial dishwasher.

In addition to cleaning any removable components, you’ll also need to keep the main body of the equipment clean and presentable. Once again, using the right materials to do so efficiently and effectively is very important.

We strongly advise against using harsh abrasives, scratchy scouring pads, pot scrubbing brushes, and similar products. These products can scratch stainless steel surfaces, degrade gaskets, and permanently damage plastic surfaces. We have observed staff that thought they were doing a good job of cleaning with a pot scrubber but were actually damaging parts of their juicer. Regular cleaning with soft non-abrasive towels and hot water is usually going to be the right answer.

NOTE: There are specific parts of certain juicers that may require the use of special tools or brushes. For example, the fine metal mesh screen used in a centrifugal juicer, or juice extractor, may best be cleaned with a specific brush. Such tools may be supplied by the manufacturer. We recommend consulting the User Manual for the correct machine-specific information.

A properly designed high quality juicer that is cleaned regularly and in line with the manufacturer’s recommendations should remain highly attractive, hygienic, and reliable for many years of service.

#6 IMPLEMENT THE RIGHT PROCEDURES

One of the most commonly asked questions we get is “How often should I have to clean my juicer?”

Our answer is typically at least once per day, but this can vary. We have some customers who juice in batches and clean the juicer immediately after juicing. Once per day is the correct answer for them. We have other customers who use the juicer all day and offer “Self-Service” juicing, where the consumer can serve their own juice. These situations may call for more frequent cleaning. Those customers may clean their juicer every four (4) hours, for example.

We have some customers who only juice oranges, while some others juice multiple fruits. When juicing oranges, lemons, limes, or even pomegranates, some customers use a shortened interim cleaning procedure. They use the shorter process between fruit to ensure the pure taste of what they’re juicing is not mixed with other fruit juices.

Cleaning with the right frequency is great for hygiene and safety reasons and is an excellent way to market fresh juice with a clean-looking juicer.

Important things to consider when drafting your internal procedures:

- When and how frequently will you clean?

- Where will you clean within your operations?

- Who will be doing the cleaning?

- Will you have internal training procedures?

- How will you train your staff?

#7 TRAIN YOUR TEAM

None of us would give our car keys to somebody who’s never driven. We shouldn’t do this with a new piece of kitchen equipment either. Investing in a professional piece of juicing equipment is like buying a new motorcycle or a new car.

We recommend a brief training to ensure your staff is informed about your new piece of equipment. The easiest and most efficient way may be to have staff watch a training video on operating and cleaning the juicer. This simple step can help lead to much higher efficiency and hygiene standards.

Many of the questions our technical experts receive from customers are questions that are covered in our training materials. The User Manual and/or the Training Videos cover a lot of topics in a well-structured format. We're happy to support our customers when they have questions, but we also know this can slow you down in the course of your operations, so we’ve made a series of videos available for cleaning and operating your juicing equipment.

Click here to view training videos.

#8 CHECK PROCESS COMPLIANCE

We’ve been in grocery stores that were absolutely beautiful. They were clean throughout: clean floors, polished apples, clean olive bars, freshly prepared self-service soup stations, and amazingly fresh salad bars. For some reason, those same stores had dirty unappealing juicing equipment. This juicing equipment was high volume equipment and had earned a lot of money. Nevertheless, it was dirty. After multiple discussions with different store managers, we've heard that the juicing equipment was a star, but the volume was off, which was quite related to staff training. When we walked the store with the Store Manager, they were very surprised to see how dirty the equipment was.

The good news: This situation can be quickly remedied. Deeds speak louder than words. A quick inspection process can fix situations like this. Give a supervisor or manager the responsibility to perform quick daily inspections to improve results. When properly cleaned and merchandised, juicers can generate more revenue than their olive and soup bars counterparts, while attracting new customers and taking up less floor space.

Communicating the importance of clean equipment and good hygiene is important. Performing quick checks and praising employees for a clean juicer can lead to some amazingly fresh results. It communicates to staff that a clean juicer is important for the operation and for the health of a business.

A clean machine sells juice and a motivated team can help keep that juicer clean and make the customers happy with freshly squeezed juice every day.

#9 REVIEW PROCESSES ON A PERIODIC BASIS

Like anything else, the only certainty we have is change. Restaurant or store layouts change. Equipment may be replaced with different models. Staff changes and we're all learning new things every day.

As operating staff gains juicing experience, they'll come up with some great ideas. These ideas may be related to being more efficient, generating more revenue, or improving operations. It’s a great idea to hear what juicing staff has to say and see if it make sense for your business.

We highly recommend periodically watching how the equipment cleaning process is going. Ask the team if there are things they feel would make it more efficient, more effective, or even more profitable. Use that feedback to review and improve the process.

#10 TRAIN NEW EMPLOYEES AND RETRAIN WHEN NEEDED

With advances in technology, training has gotten much easier. Video technology and the internet are powerful tools for efficiency. We have to work smarter.

The ease of access to video and new virtual tools means there are no excuses with regards to training. Technology makes it relatively easy to properly train staff on operating and cleaning your juicer. Some customers choose to film their own staff operating and cleaning their juicer equipment. Some customers choose to use videos we make available.

Besides our available training videos, Citrus America can help you develop a customized training strategy. We can help you develop the right training strategy to fit your needs based on the latest in juicing know-how.

SUMMARY

Fresh juice is a great way to enhance any food retail or food service location and impress your customers. It's important to clean your commercial juicer regularly. This is a great way to promote your business, support your brand, be safe, and extend equipment life.

Juicing is a team effort. Following the above TEN PRINCIPLES can help you implement the right strategy to keep your equipment looking and functioning at its best.

About Citrus America: Citrus America has been driving innovation and quality in the juicing segment for more than a decade in North America and the Caribbean. We’re the exclusive master distributor for Citrocasa and have driven many innovations and quality improvements in juicing equipment. In addition to equipment solutions, we provide tailored training and support strategies to help our customers earn Healthy Profits.